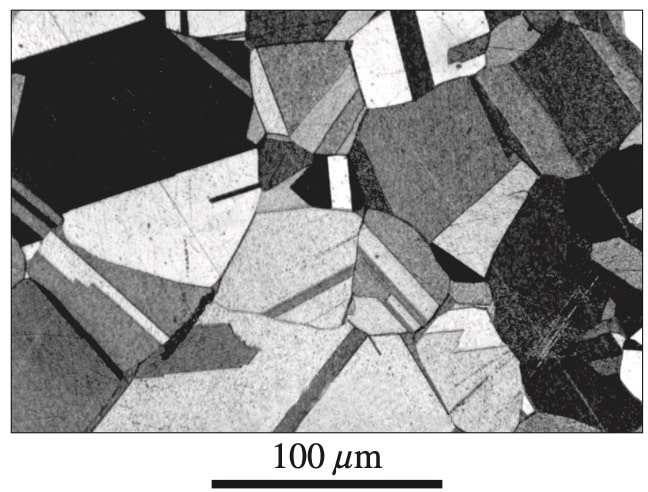

The image shows the microstructure of brass.

What type of grain structure does this image represent?

- Deformed

- Dendritic

- Equiaxed

- Stressed

Aussie Maths & Science Teachers: Save your time with SmarterEd

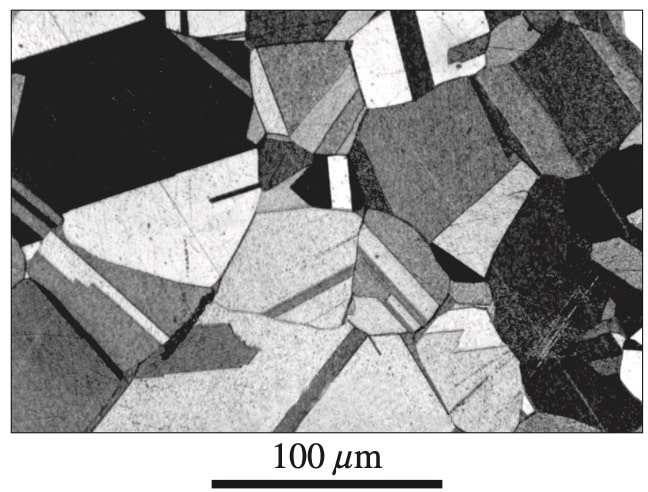

The image shows the microstructure of brass.

What type of grain structure does this image represent?

`C`

`=>C`

Structural steel `text{I}`-beams are used to make a crane were hot-rolled then normalised.

Explain why normalising was chosen as the heat treatment process. Support your answer with a labelled sketch of the resulting microstructure. (4 marks)

--- 8 WORK AREA LINES (style=lined) ---

--- 0 WORK AREA LINES (style=lined) ---

A small truck chassis rail has been made from rectangular hollow section (RHS) steel. The RHS has been cold formed from an alloy steel with a yield strength of 500 MPa. A manufacturer's sign on the chassis rail is shown below.

--- 6 WORK AREA LINES (style=lined) ---

--- 5 WORK AREA LINES (style=lined) ---

i. Welding

Drilling

i. Welding

Drilling

Normalised high-tensile steel has been chosen for the manufacture of a wing support beam.

--- 0 WORK AREA LINES (style=lined) ---

--- 4 WORK AREA LINES (style=lined) ---

i. Microstructures

ii. The strength of the steel is markedly increased.

i. Microstructures

ii. The strength of the steel is markedly increased.

Steel `text{I}`-beams have been used when large, open spans need to be created inside buildings.

Explain how microstructural changes take place in steel when an `text{I}`-beam is formed using the process of hot rolling. You may use a drawing to support your answer. (4 marks)

--- 9 WORK AREA LINES (style=lined) ---

The grain structure of a material has changed over time from that shown in microstructure `A` to that shown in microstructure `B`.

What heat treatment process has the material undergone to cause this change?

`D`

`=>D`