Describe the process of compression moulding when used to manufacture aircraft components. (3 marks) --- 7 WORK AREA LINES (style=lined) ---

ENGINEERING, AE 2023 HSC 21d

ENGINEERING, PPT 2018 HSC 26d

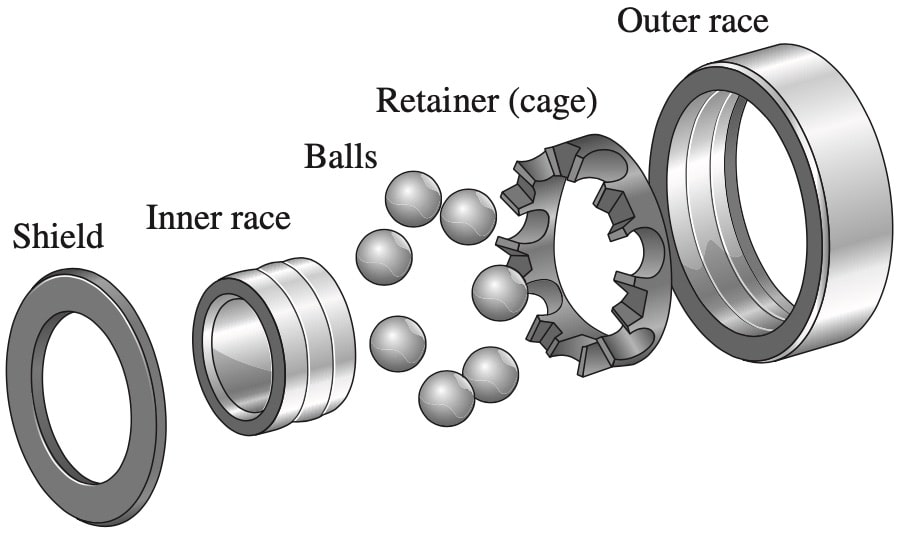

The components of the bearing assembly used in the fidget spinner are shown.

The retainer can be made from either glass fibre-reinforced nylon or stainless steel.

Compare the in-service properties of these materials for use in the retainer. (4 marks)

--- 8 WORK AREA LINES (style=lined) ---

ENGINEERING, AE 2019 HSC 25b

Some materials have properties that allow them to be used in the manufacture of both modern racing yachts and aircraft. These materials include Kevlar® aramid fibre, carbon fibre epoxy composites and aluminium alloys.

Complete the table by providing a property which makes each of these materials suitable for the manufacture of both yachts and aircraft. (3 marks)

--- 0 WORK AREA LINES (style=lined) ---

ENGINEERING, AE 2021 HSC 10 MC

The diagram illustrates a method of forming a thermosetting polymer.

Which method is illustrated?

- Extrusion

- Calendering

- Injection moulding

- Compression moulding